Our Services

-

NFPA 99 Compliant Medical Gas Verification, Inspections & Testing

NFPA 99 verification for new and existing systems, with full documentation and all required testing. Knowledge of all local, state, and federal compliance.

-

ASSE 6000 Series MedGas Training

On-site or off-site training and certification of ASSE 6005 (MedGas Generalist), 6010 (MedGas Installer), 6020 (MedGas Inspector), 6040 (MedGas Maintenance) to empower your team and bolster your services.

-

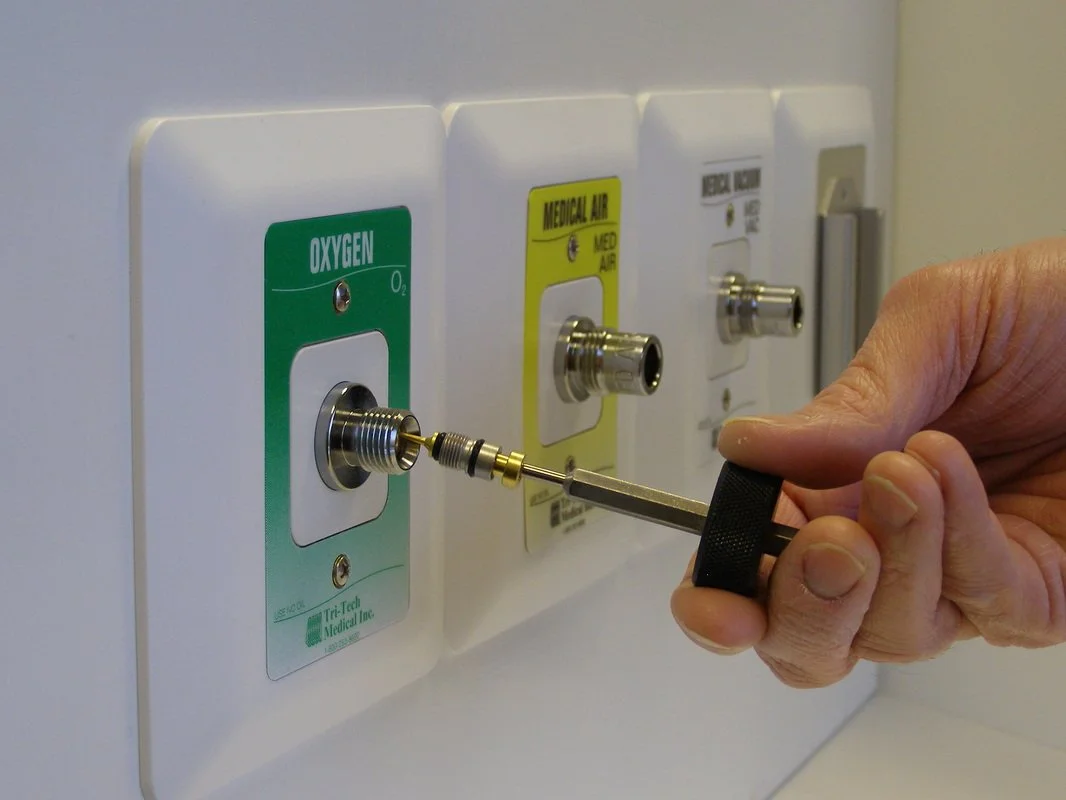

Medical Gas Equipment

We supply, install, and maintain high-quality medical gas equipment for healthcare facilities of all sizes. From source equipment like manifolds, compressors, and vacuum pumps to outlets, alarms, and zone valve boxes, every product meets NFPA 99 standards for safety and compliance. Our team ensures each component is correctly integrated, tested, and documented, so your system operates reliably and supports the highest level of patient care..

-

Responsible Facility Authority (RFA) Services

We provide certified Responsible Facility Authority (RFA) services to oversee every aspect of your medical gas and vacuum systems — from design and installation to maintenance and inspection readiness. Our expertise ensures your facility meets NFPA 99 2021+ standards, passes inspections, and protects patient safety.

Compliance Verification & Testing

Ensure every system meets NFPA 99 safety standards.

We provide certified medical gas system verification for new installations, renovations, and existing facilities. Our testing process includes pressure checks, leak detection, alarm function tests, and documentation to ensure full NFPA 99 and 55 compliance. Whether you’re preparing for accreditation or healthcare inspections, our verification services give you peace of mind that your system is safe, reliable, and audit-ready.

What’s Included:

Full NFPA 99 verification

Pressure & vacuum flow testing

Full Alarm system testing

Comprehensive compliance documentation

Particulate Analysis

Halogenated and Liquid hydrocarbon testing

Dew Point Analysis

Verification of required credentials for all work

ASSE 6005 – Medical Gas Systems Generalist

For personnel who require a basic working knowledge of medical gas systems but will not be performing installation or maintenance.

Topics Covered:

Medical gas and vacuum system overview

NFPA 99 code basics

Safety protocols & hazard awareness

Understanding system components and functions

Training & ASSE 6000 Series Certification

Empower your team with compliance-focused skills. All classes taught by ASSE 6050 compliant instructors.

ASSE 6010 – Medical Gas Systems Installer

For installers responsible for the assembly and installation of medical gas and vacuum systems.

Topics Covered:

NFPA 99 installation requirements

Piping and brazing techniques for medical gas systems

System testing & documentation procedures

Compliance verification steps prior to turnover

Provides required ASTMB brazing requirements and sectioning

*All components necessary for required sectioning not included with this training

ASSE 6020 – Medical Gas Systems Inspector

For inspectors (Not Verifiers) who evaluate installations to ensure compliance with codes and standards. Generally county, state, or federal government employees.

Topics Covered:

NFPA 99 and ASSE inspection procedures

Verifying material and installation standards

Pressure testing & system verification methods

Documentation and reporting best practices

Knowledge of required credentials

AHJ Responsibilities

ASSE 6040 – Medical Gas Maintenance

We deliver on-site and off-site training programs that prepare your staff to operate and maintain medical gas systems safely and in compliance with NFPA 99 and 55. Our courses cover system operation, troubleshooting, and preventive maintenance best practices. We also provide certification prep for ASSE 6040-series, tailored to your facility’s needs.

Training Topics:

NFPA 99 code requirements

Safe operation & emergency procedures

Preventive maintenance best practices

ASSE 6000-series certification preparation

Safe shutdown Compliance

Enables onsite Employees to recognize contractor performance

Please complete and return application to Phillipsmgs@verizon.net for actual class registration

Medical Gas Equipment Sales, Design & Installation Services

Reliable, code-compliant equipment for every facility.

We supply, install, and integrate high-quality medical gas equipment, from source systems to patient room outlets. Every product we provide meets NFPA 99 standards and is installed to exacting specifications. We handle manifolds, air compressors, vacuum pumps, alarms, zone valve boxes, and more, ensuring seamless operation and long-term reliability.

Equipment We Provide:

Manifolds and source gas systems

Medical air compressors & vacuum pumps

Alarm panels & monitoring systems

Outlets and zone valve boxes

Dew Point and CO Monitors

Flow Meters and Vacuum Regulators

Replacement Valves and Gauges

Medical Gas and Vacuum Pipe Labels

Anesthetizing location drop hoses

Tritech Medical conversion kits

Nitrogen control Panels

Oxygen Safe products

Responsible Facility Authority (RFA) Services

Dedicated oversight to ensure full NFPA 99 2021 and up compliance.

As defined in NFPA 99 section 5.1.14.1: the Responsible Facility Authority (RFA) is the individual charged with making final decisions regarding the design, installation, testing, maintenance, and operation of your facility’s medical gas and vacuum systems. We provide professional RFA services to act as your facility’s trusted compliance leader — ensuring every aspect of your medical gas systems meets code, passes inspections, and supports patient safety.

Our RFA Services Include:

Acting as the point of authority for all medical gas system compliance matters

Reviewing and approving design and installation plans

Coordinating with installers, verifiers, and inspectors

Overseeing maintenance schedules and emergency response procedures

Organizing and overseeing facility system shutdowns

Maintaining complete compliance documentation and records

Why It Matters:

Having an experienced, certified RFA reduces compliance risk, prevents costly project delays, and ensures your systems are always ready for accreditation surveys and inspections.